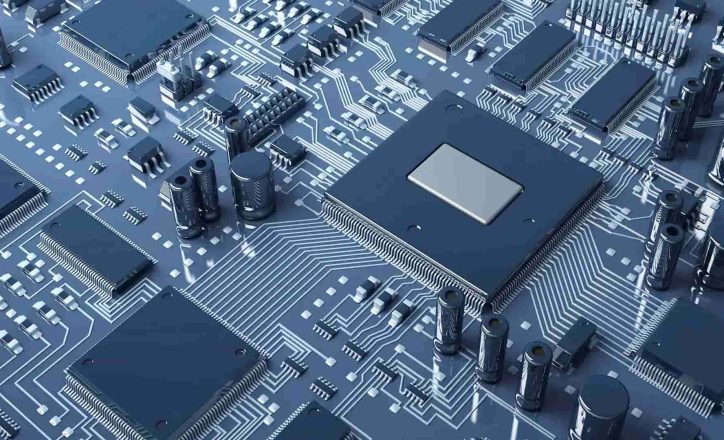

Rapid Prototyping and On-Demand Production for

Semiconductor Industry

Accelerate your semiconductor manufacturing process with outstanding prototyping and innovative product development. Cost-effective and higher-level manufacturing solutions for the growing demands of the semiconductor industry.

- Superior-quality semiconductor equipment

- Instant pricing & free DFM feedback

- 24/7 engineering support

Why RapidDirect for Semiconductor Industry

We offer superior semiconductor manufacturing solutions, from material & process selection to prototyping and mass production. With a perfect mix of technical expertise and manufacturing implementation, we effectively bring your semiconductor equipment to life.

Powerful Capabilities

Being an ISO 9001:2015 certified organization, we guarantee that your industrial equipment components are manufactured utilizing the most suitable materials and techniques, like CNC machining, sheet metal fabrication, die casting and more.

Instant Quotation

We offer a streamlined experience for industrial equipment prototyping and custom manufacturing. Our instant quotation platform provides instant pricing and lead times, along with DFM analysis feedback. You can easily manage and track your orders through our platform.

High Precision Parts

RapidDirect specializes in custom manufacturing of industrial equipment parts that meet precise requirements. Our manufacturing capabilities enable us to produce industrial parts with tolerances as tight as +/- 0.001 inches.

Fast Cycle Time

Get quotes within minutes and parts within days! With high manufacturing skills and technical experience, our expert engineers will work to reduce cycle time by up to 50%.

Prototyping & Production Solutions for Semiconductor Industry

Get top-notch in-house prototyping and production services for simple and compound semiconductors. RapidDirect specializes in fast-turn prototypes for semiconductors testing and design iteration. We ensure a smooth run of the semiconductor manufacturing cycle and help refine your design principle and solidify your ideas before mass production.

Prototyping

Bring your early-stage medical designs to life with prototypes crafted from production-grade materials. Our process enables you to evaluate and optimize your designs, ensuring they are fully functional and ready for testing.

Prototyping

Our experienced technicians will bring your design to reality by carefully analyzing your design file and crafting prototypes to match your specifications precisely. Tailored to meet the demands of your application, we carefully select the materials and techniques to ensure your prototypes look and function like the final product.

Engineering Validation and Testing

Refine your robotics prototypes with quick and easy changes after rigorous engineering testing and validation of performance standards.

EVT

Our functional prototypes, designed to mimic the final product, provide you with a clear visual representation of your design, allowing for easy identification of any potential issues. We guarantee quality and reliability from the beginning by analyzing and fine-tuning every aspect of your prototypes.

Design Validation and Testing

Evaluate the performance, functionality, and aesthetics of your medical product with precision. Save valuable time and resources by making design improvements during the prototype stage.

DVT

Our expert design team provides in-depth feedback on the manufacturing feasibility of your prototypes, helping you assess their performance and appearance. We offer an extensive range of materials, finishes, and mechanical designs to craft components with ideal end-use functionality and market-ready finishes.

Production Validation and Testing

Streamline your designs for large-scale production with our production-grade manufacturing capabilities and expert quality control.

PVT

Gain valuable insight into your product design with expert feedback from our technical team. This allows you to evaluate the manufacturability and suitability of your robotic part and make final refinements for a streamlined production process.

Mass Production

Effortlessly move into mass production with the swift delivery of end-use parts and the seamless integration of your quality standards into RapidDirect’s manufacturing process.

MP

Take your custom robotics manufacturing to new heights with our cutting-edge manufacturing techniques. Our team of experts works to ensure your products meet quality and performance requirements, keeping costs low and lead times short.

Trusted by Fortune 500 Semiconductor Companies

Work with a long list of Fortune 500 semiconductor companies to dynamically streamline manufacturing capacities. From Integrated Device Manufacturers to End Systems Producers, RapidDirect delivers efficient solutions for improved performance.

- Semiconductor design and production firms

- Computer chip manufacturers

- Networking equipment producers

- Internet of Things (IoT) manufacturers

- Telecommunications companies

- OEM design studios

- Technology startups

- Consumer electronics device manufacturers

- Energy technology companies

Manufacturing Capabilities for Semiconductor Components

Semiconductor manufacturing requires a fine-tuned synergy of processes and technology, and we deliver this efficiently. At RapidDirect, our software solutions, expert technicians, and manufacturing technology work harmoniously to help you get your semiconductor fabrication right from the start.

CNC Machining

Leverage the power of CNC Machining for versatile, accurate, and efficient production of parts across various industries.

Precision Machining

Choose Precision Machining for the utmost accuracy and quality in producing complex components.

5 Axis CNC Machining

Benefit from the flexibility of 5 Axis CNC Machining, enabling multi-directional cutting for intricate parts.

CNC Turning

Achieve precision cylindrical and symmetrical parts using CNC Turning, ensuring consistent and reliable results.

CNC Milling

Opt for CNC Milling to efficiently create intricate shapes and designs on various materials with high precision.

Semiconductor Industry Applications

Semiconductor manufacturing requires a fine-tuned synergy of processes and technology, and we deliver this efficiently. At RapidDirect, our software solutions, expert technicians, and manufacturing technology work harmoniously to help you get your semiconductor fabrication right from the start.

Check out our incredible line of well-functioning 5-axis machining centers ranging from the best 5-axis horizontal machining center to top-notch vertical machining centers. These are ideal facilities for manufacturing components for various industries. We combine advanced technologies with skilled technicians to deliver results to suit your needs perfectly.

- Smartphone components

- Communication devices

- Solar cells

- Smart homes devices

- Computer chips

- Photomasks

- Game console devices

- Lithography optics

- Rectifiers

- Field-effect transistors

See What Our Customers Say About Us

A customer’s words have a more substantial impact than a company’s claims – and see what our satisfied customers have said regarding how we fulfilled their requirements.

Piscary Herskovic

Product Designer

Mark Alford

Chief Engineer

Luc Szorc

Mechanical Engineer

Kayne Espinosa

Project Manager

Hari Mackenzie

Engineer

Custom Prototypes and Parts for Semiconductor Companies

RapidDirect creates custom prototyping and production solutions for the semiconductor industry by integrating new technologies, machine learning, and analytics. Our operational efficiency and ability to meet customer demands ensure that we help you stay in competition and achieve business goals.

Ultimate Guide to CNC Machining

Why Choose Us for CNC Milling Service

At RapidDirect, we are committed to helping you reach your manufacturing goals. We constantly strive for effective solutions through our progressive technological approaches and machining techniques. Our CNC milling services ensure you get highly precise prototypes and production parts with superior quality.

Aerospace

Consumer Goods

Medical Devices

Automotive

Explore Related Resources

Multi-Axis Machining: 3-Axis vs 4-Axis vs 5-Axis CNC Machining

Selection of the right type of machine in multi-axis CNC machining is among the most crucial decisions. It determines the overall capabilities of the process, the designs that are possible, and the overall costs. 3-axis vs 4-axis vs 5-axis CNC machining is a popular debate and the right answer depends on the requirements of the project. This guide will…

CNC Machining Materials: Choosing the Right Materials for CNC Machining Project

CNC machining is inarguably the lifeblood of the manufacturing industry with applications such as aerospace, medical devices, and electronics. In recent years, there have been incredible advancements in the field of CNC machining materials. Their wide portfolio now offers great combinations of material properties, cost, and aesthetics. In this article, we will delve into the diverse world…

Plastic CNC Machining: Create Custom CNC Machined Parts with Accuracy

A common depiction of CNC machining, most times, involves working with a metallic workpiece. However, not only is CNC machining widely applicable to plastics, but plastic CNC machining is also one of the common machining processes in several industries. The acceptance of plastic machining as a manufacturing process is due to the wide array of plastic CNC…